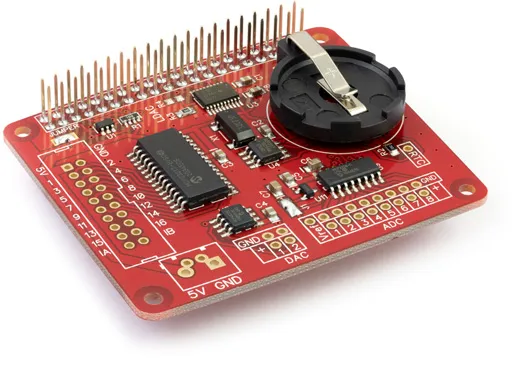

Below is a photographic overview of how we produce our own printed circuit boards (PCBs) using a UV light box and chemical etching. This method is ideal for hobbyists and electronics enthusiasts looking to create customised boards at home for projects and prototypes.

Disclaimer: Always wear appropriate safety gear, including gloves, goggles, and protective clothing, when handling chemicals or operating UV light boxes. Do not attempt this process unless you are confident in your ability to handle acids and other reactive substances safely. Improper handling can result in serious injury or damage.

Step 1: Create a Stencil on Transparency Film

Begin by preparing a stencil of your PCB layout. This should be printed onto transparency film, preferably using a laser printer set to its darkest print settings. It is crucial that the black areas of the print are completely opaque, as any gaps or faint areas will allow light to pass through and affect the final etch. If any part of the design appears incomplete, you can reinforce it using permanent marker directly on the film.

Step 2: Expose the Board Using a UV Light Source

Place your UV-sensitive PCB board underneath the stencil and expose it to UV light. Exposure time will vary depending on the type of board and the strength of your light source. Commercial UV boxes typically take a few minutes. In our case, using a DIY UV box built from an old scanner housing, we find that 50 seconds is sufficient for a full exposure.

Step 3: Develop the PCB

Immediately after exposure, submerge the board in a photo developer solution. This process will dissolve the UV-exposed photoresist, revealing the copper tracks underneath as defined by your stencil. The unexposed areas will remain protected.

Step 4: Etch the Board

Once developed, the board is ready to be etched. We use ferric chloride, supplied in a powdered form and mixed with water. Etching is significantly more effective when the solution is warmed. A bubble etching tank with a built-in heater is ideal, but placing the acid tray in a container of hot water can also help. Agitate the tray gently to ensure even coverage. For small boards, etching typically completes in about 20 minutes using this method.

Step 5: Remove the Photoresist

After etching, clean off any remaining photoresist to reveal your copper tracks. We use isopropyl alcohol for this, although commercial photoresist strippers are also available and may provide a more thorough clean.

Step 6: Drill the Holes

With the copper tracks now exposed and clean, the final step is to drill any required holes for through-hole components. Once drilled, the board is ready for use in your project.

Tips and Troubleshooting

If the board is overexposed, as shown on the left-hand example in the accompanying image, you may notice excessively thin or broken tracks. This can lead to unreliable connections or complete circuit failure. The circled areas in the image indicate component locations for 0805 resistors and surface-mount MOSFETs, which require accurate track width for proper soldering and performance.

Comments