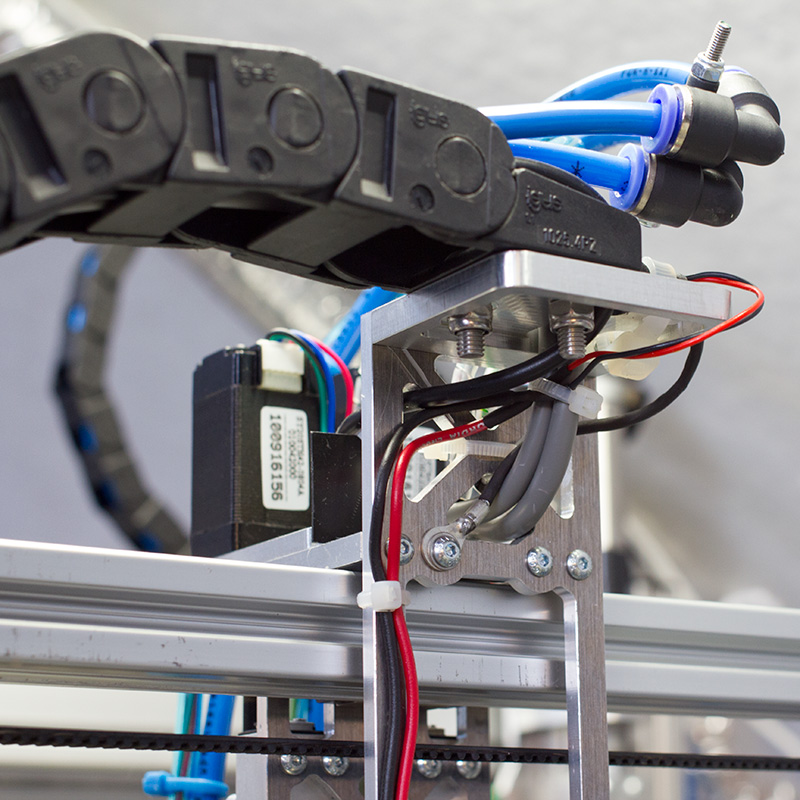

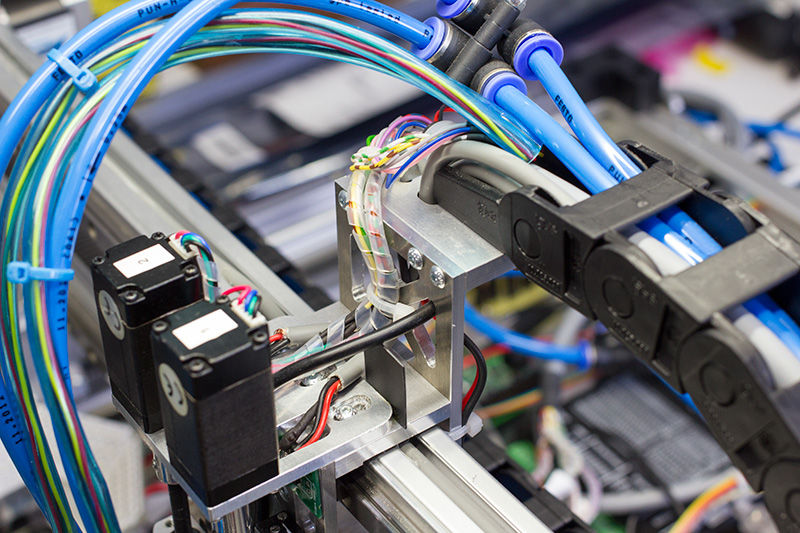

In the past few weeks, we had an intermittent problem with two of the stepper motors on the DIY Pick and Place machine on the picker head where the motors wouldn’t always run at slower speeds when the head was at the far end of the main X-Y bed.

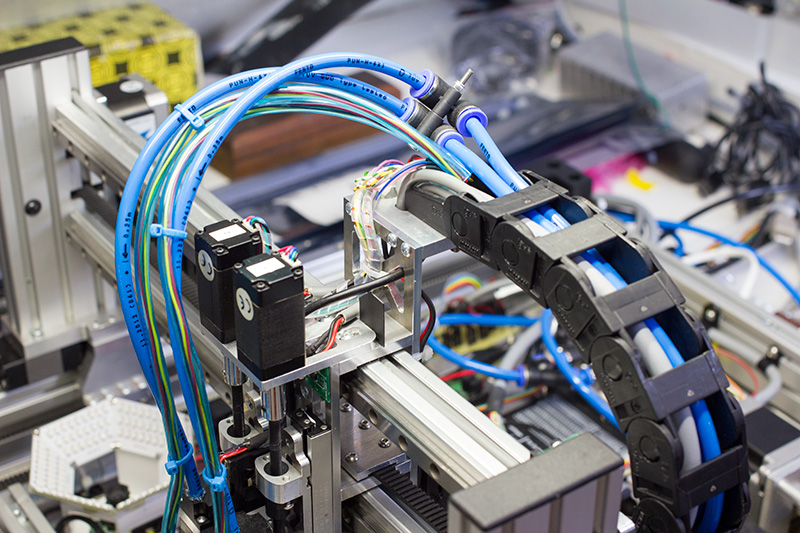

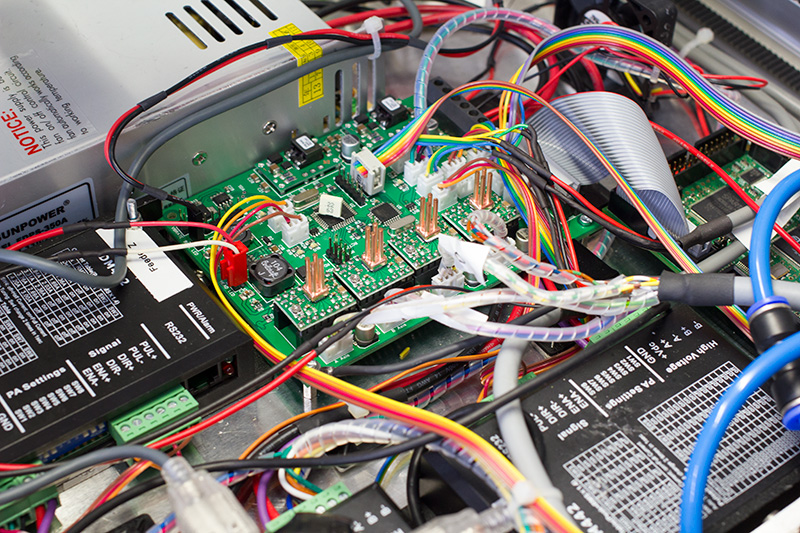

We tracked the fault down to a pair of broken wires in the main 24-way cable which runs from the controller board and motor controllers to the head assembly driving the steppers and head lighting system. The cable we had used was a Belkin printer cable and this wasn’t designed to be repeatedly folded as the e-chains moved.

As a temporary fix, we added two new single-core wires to the controller and ran this along the e-chains to restore power to the steppers.

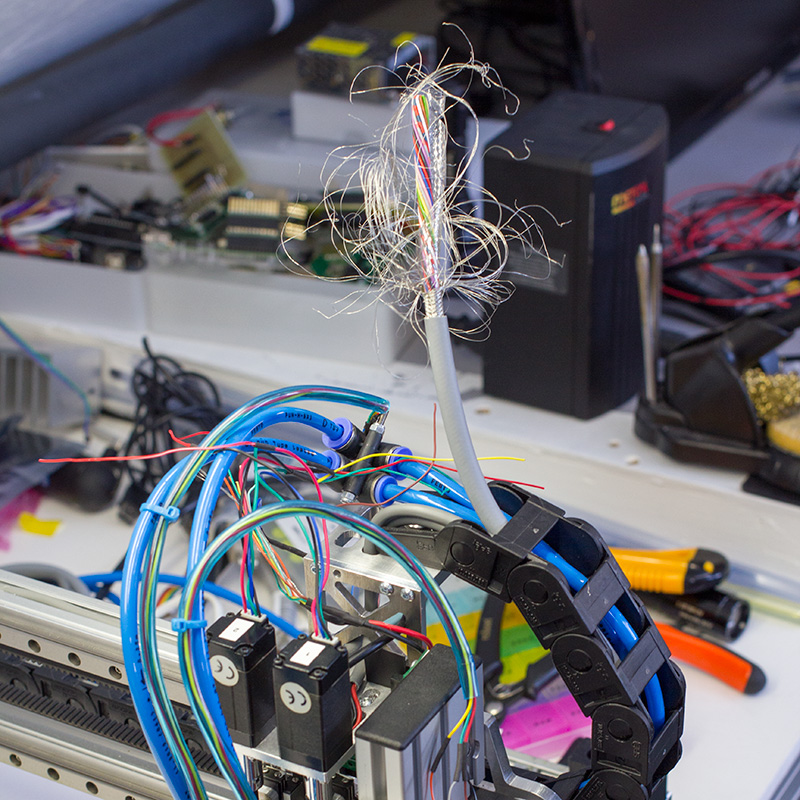

I ordered three meters of Chainflex® CF240 data cable from igus GmbH (www.igus.co.uk) which is an 18 core with a 0.25mm cross-section on each core flexible data cable which is designed to be used in e-chain systems.

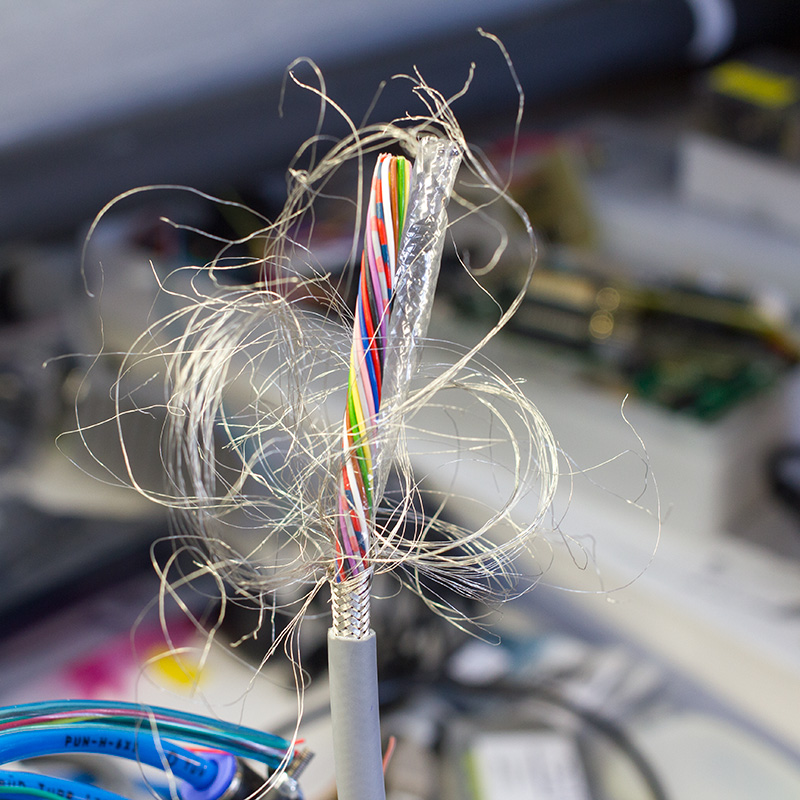

The new cable has a fully shielded design with a very high-quality metal braid which we have connected to the main chassis and also onto the picker head to earth the head assembly to the chassis.

The cost of the new cable with shipping was £24.37 and it arrived a few days after placing the order.

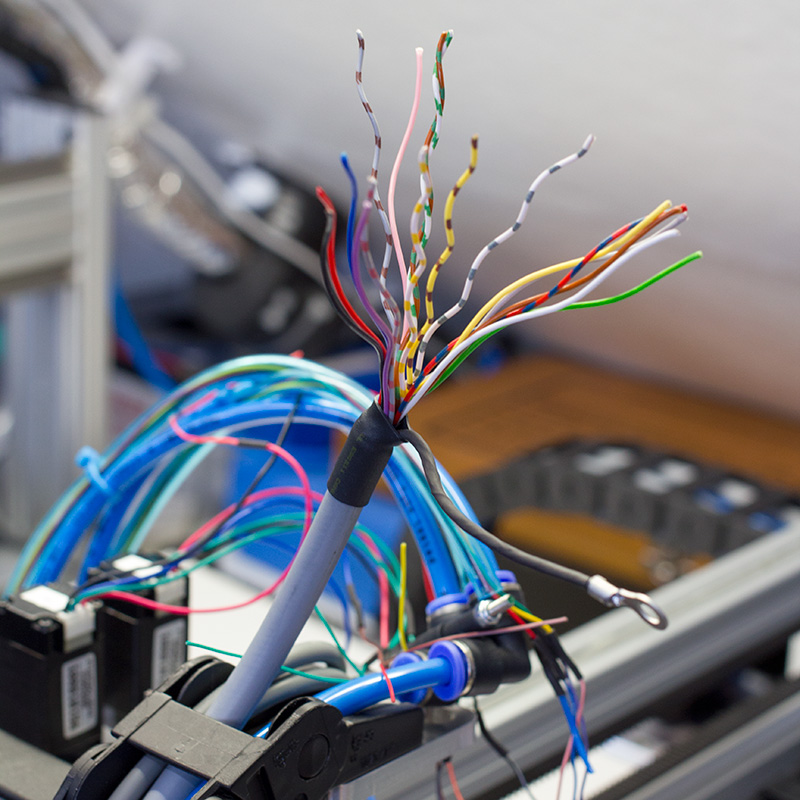

The cores on the new cable are much larger than the old printer cable and so the power losses should now be lower than before and with the additional screening, it should also reduce any interference from the limit switch sensor wires which run alongside the new cable.

It took approx. 3 hours to make a list of the old colours used, remove the old cable, prep and then install the new cable into the Pick and Place machine and all the stepper motors worked the first time when testing the machine.

Comments