Our Axminster SIEG Super X1 Micro Mill has had many upgrades since we purchased it over 10 years ago but it has always stood on the same MDF table in the loft which had limited storage for the milling and lathe cutters and other machining tools.

To resolve this, we decided to build a new table and storage area using 18mm plywood with a built-in drawer unit to fit into the loft.

The top and sides are made from 18mm plywood while the drawers are made from 18mm plywood for the sides and 9mm plywood for the drawer bases.

We also added a wide shelf on runners for the CNC mill PC keyboard and mouse and a fixed wide shelf for the PC and other larger tools.

CNC Mill Driver Board

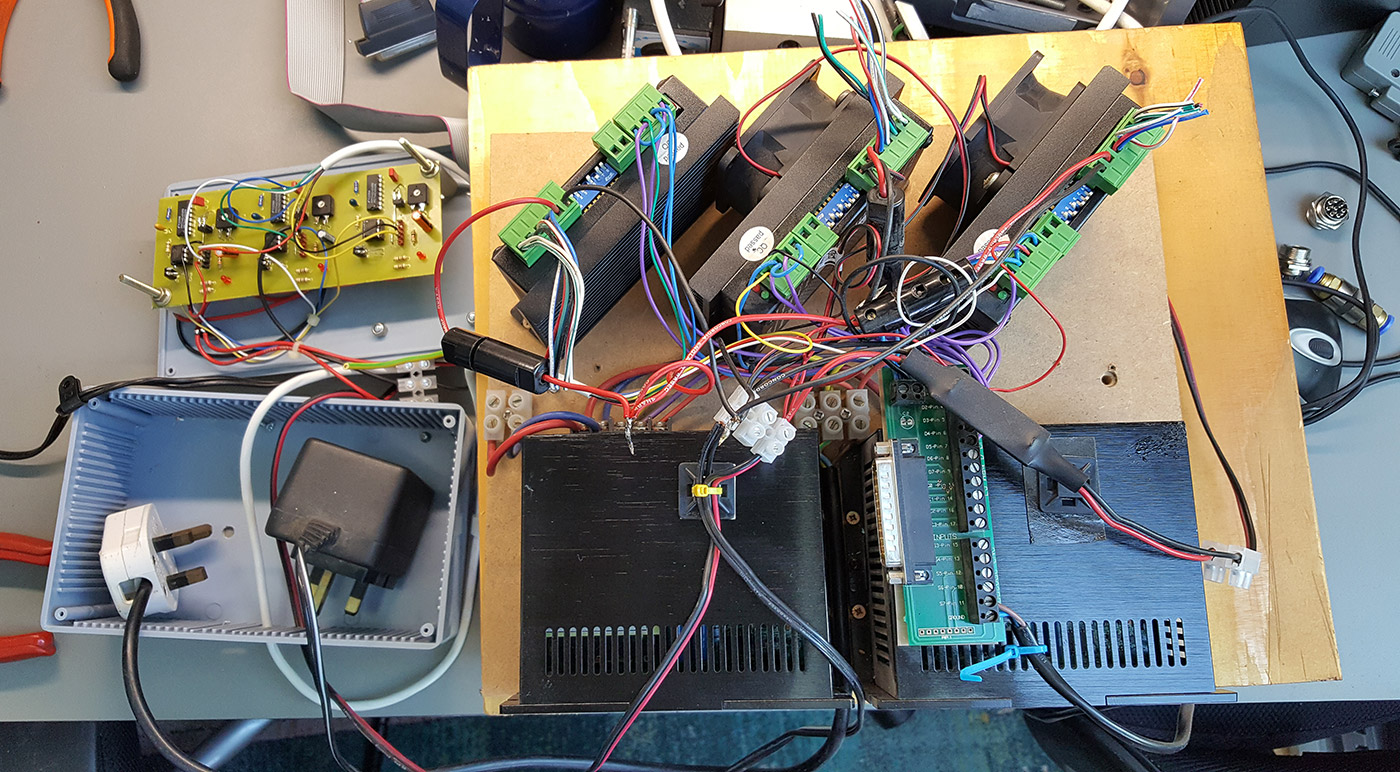

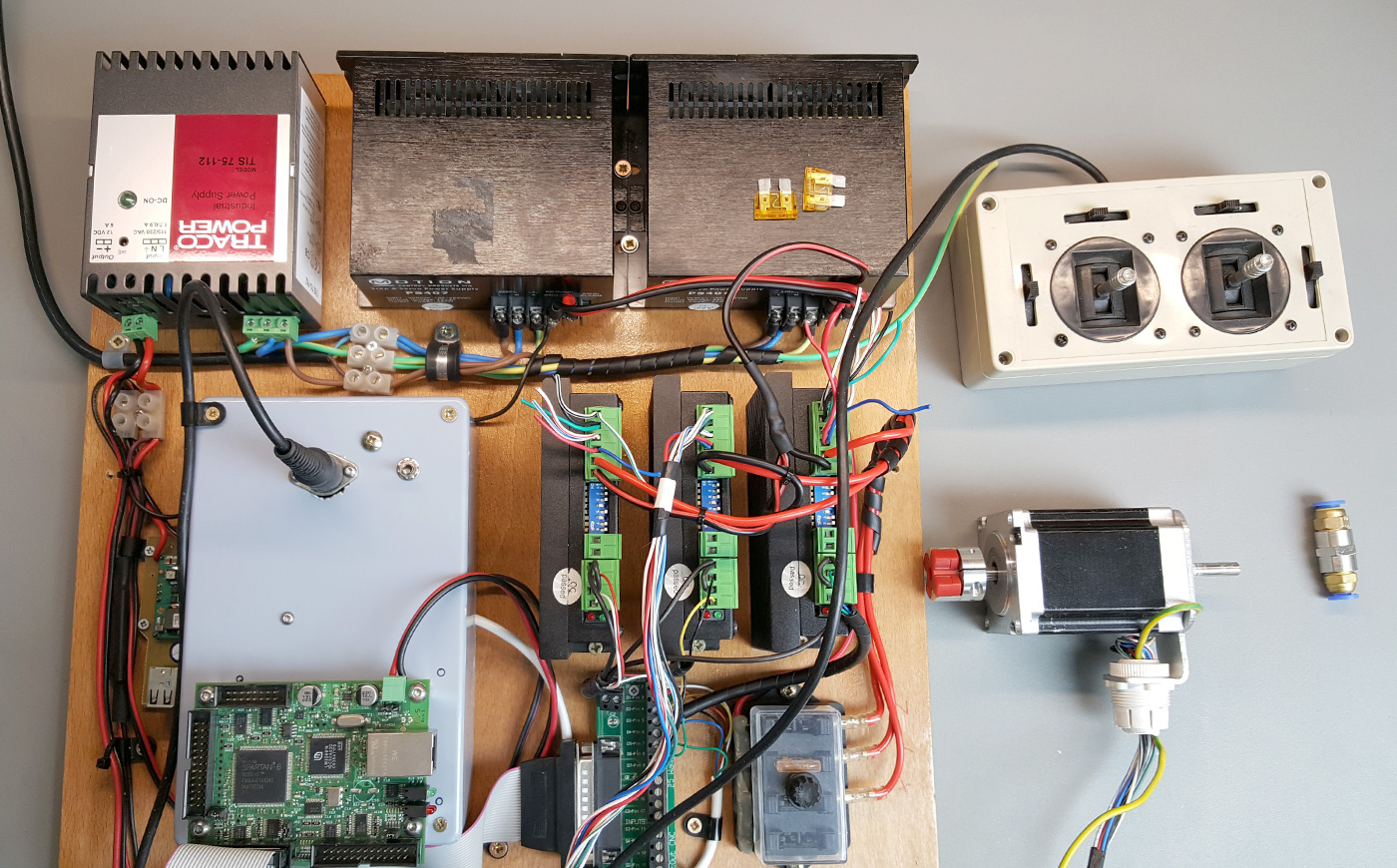

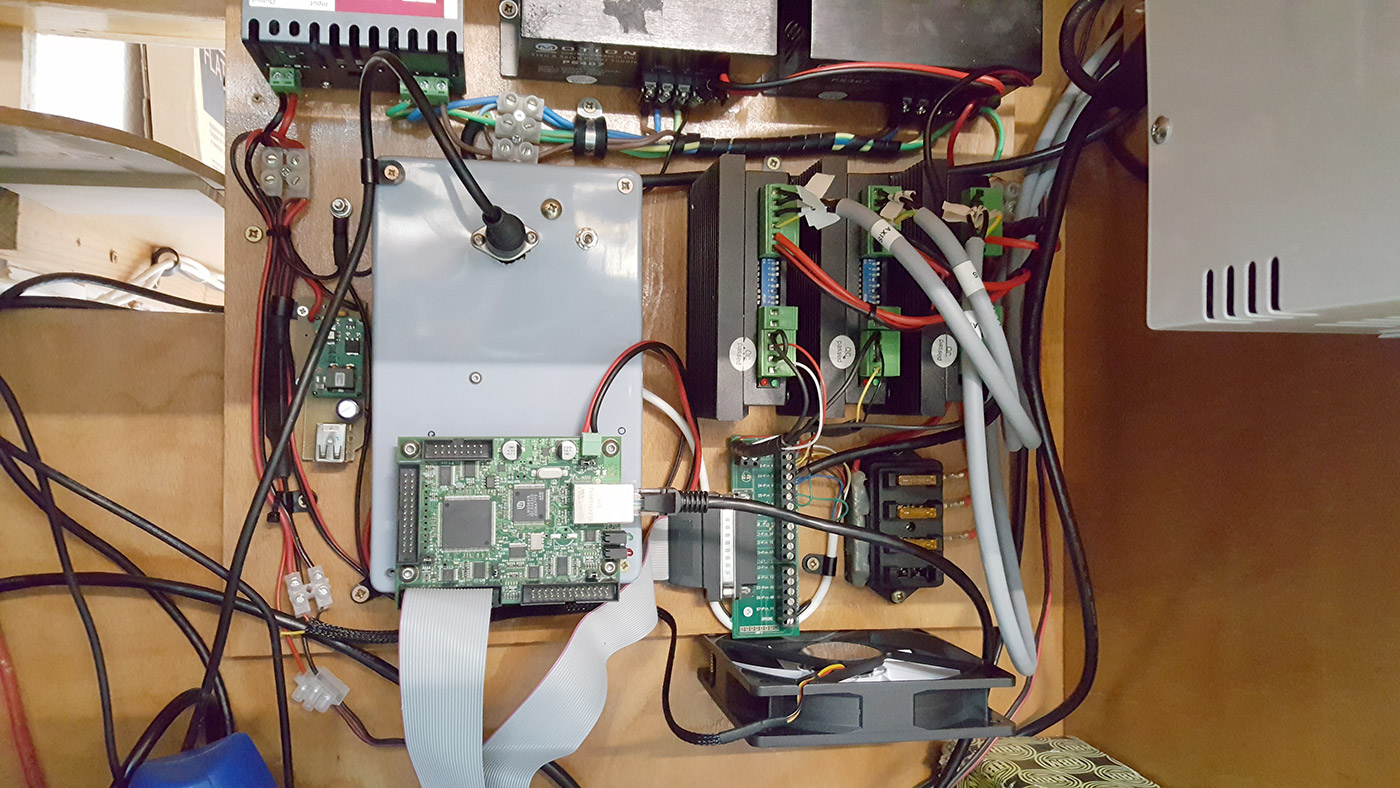

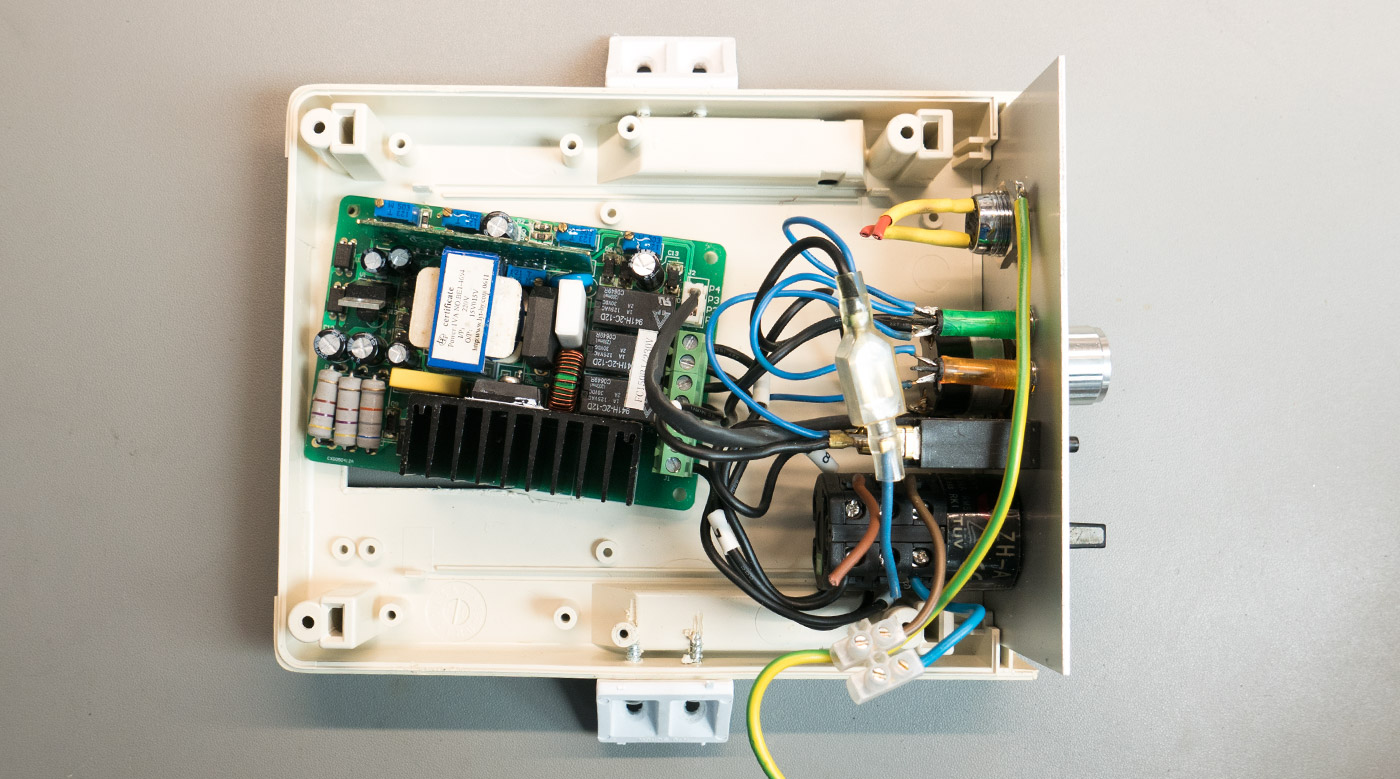

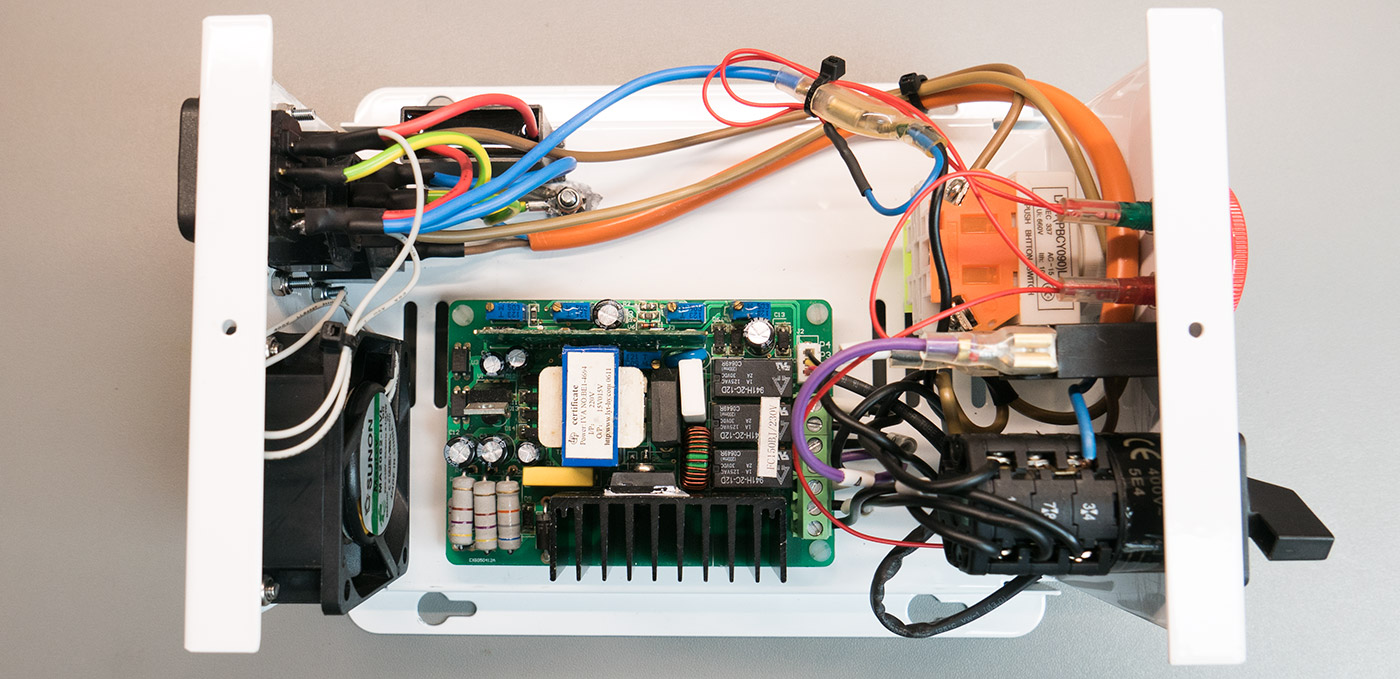

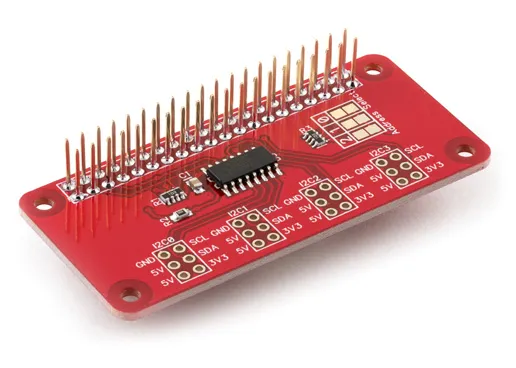

The CNC mill driver board was originally built using several plug-in power supplies for the 12V and 5V parts of the circuit. We replaced this with a new layout using a 12V Traco Power power supply and a 5V switching converter to bring the 12V down to 5V for the hand mill controller. We also replaced the old parallel interface on the PC which was driven by Mach 3 to use the Ethernet Smoothstepper controller we had previously used on the soldering robot project.

With the Smoothstepper controller we now have much faster and smoother motion of the stepper motors and the old Dell PC which ran Windows XP has been replaced with a new modern system running Windows 10.

The LED driver for the mill head was also fitted to this board but we may change to a variable brightness controller later.

The 48V power for the stepper drivers uses blade fuses via a mounted fuse box which replaced the old inline fuses used previously.

Mill Motor Driver Replacement

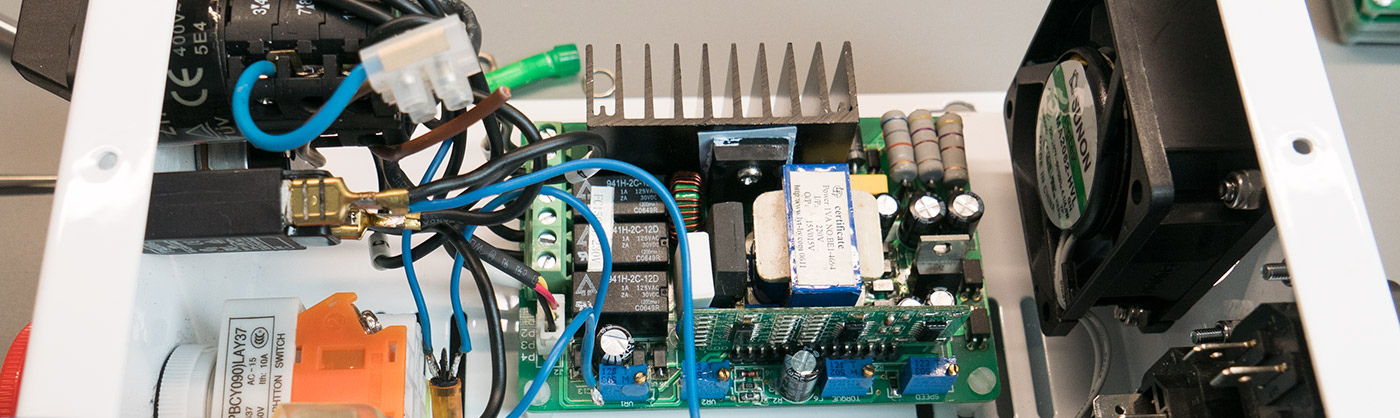

Whilst working on new upgrades for the Z axis on the mill the motor driver board overheated released the magic smoke and failed and so we had to find a replacement driver board.

The mains powered control board is marked as X1-121A or FC150BJ but all of the UK suppliers we found no longer stock this board and it has been discontinued and replaced with a new model but the suppliers couldn’t confirm if the new model would work with our mill. We then found a supplier in Luxembourg www.rcm-machines.com/en who had the older model in stock and the board arrived a few days later.

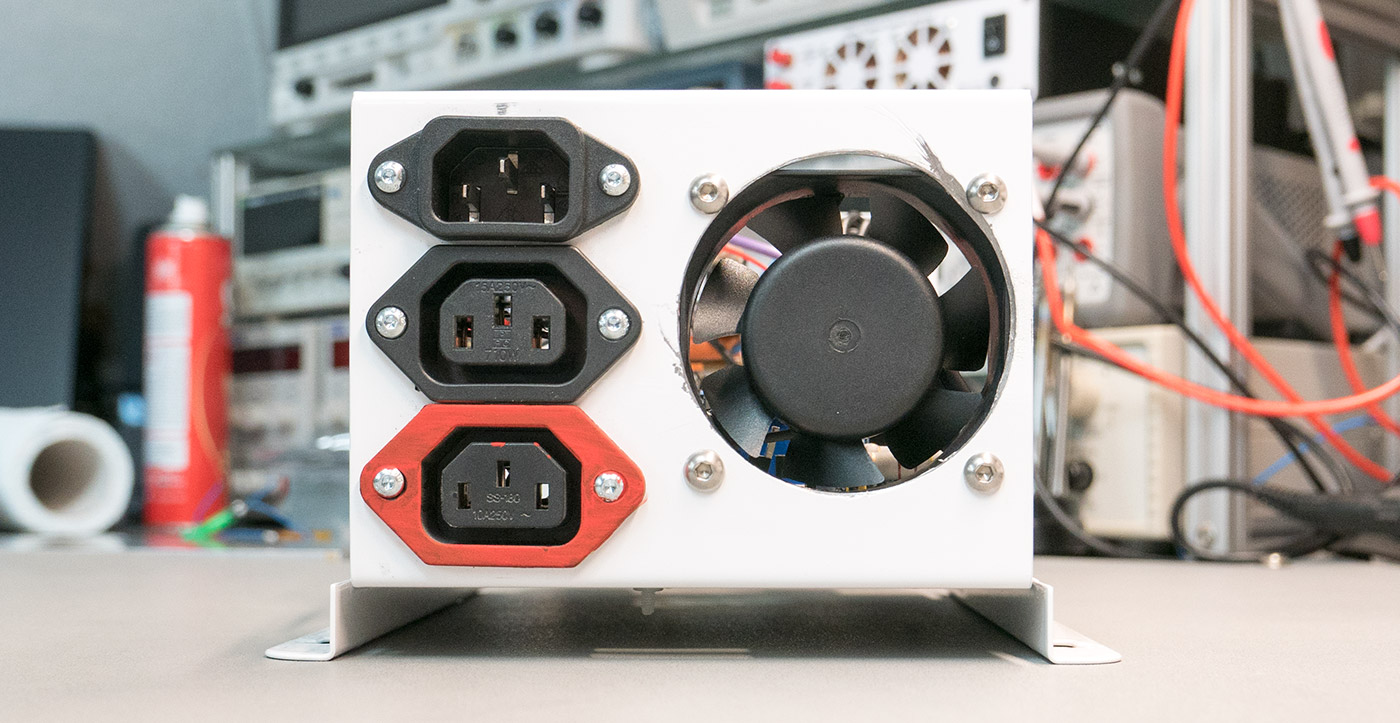

To avoid overheating issues and ensure better airflow over the motor board we decided to use a new metal case with a cooling fan which runs from 240V. We also installed an emergency stop button and added power in and out sockets on the back of the case so we can shut everything down if needed in an emergency.

I also created the following short video which was recorded on the GoPro Hero 7 Black showing the work in progress.

Comments