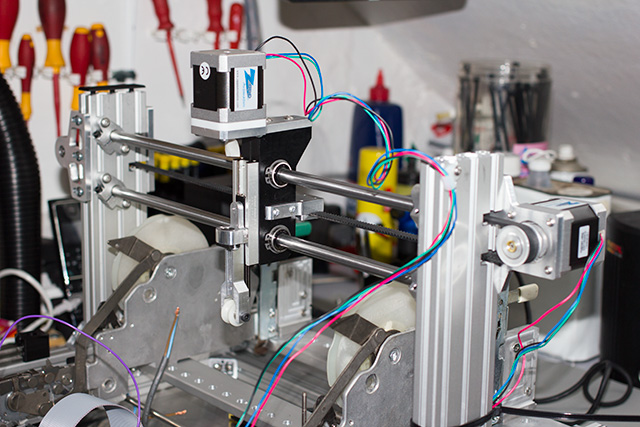

The feeder activator system to select the correct component feeder and then activate the feeder is based on the same system used on the semi-automatic pick and place machine we built before.

In order to save weight on the activator head we decided to use a smaller Z-axis bearing assembly and use unhoused X-axis bearings fitted into a 22mm thick Delrin plastic support bracket.

The bearings and 10mm shafts were ordered from an eBay Chinese supplier.

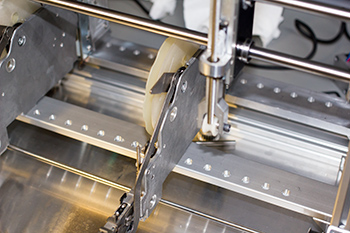

After the activator was assembled we found that the cheap Chinese bearings had very excessive play and movement and the activator would not run without juddering and shaking when driven with the stepper motor.

Due to the excessive movement with the bearings, we are going to have to scrap this version and order higher quality bearings and shafts and rebuild all the associated feeder activator parts again.

The Z-axis bearing and drive leadscrew for the feeder activator system with main bearings on the X-axis 10mm shafts.

The feeder base plates have been drilled with 8mm holes to accept up to 16 tape component feeders with space for chip feeders on each side.

The excessive movement on the bearings can be seen in the video below.

Comments